So again, take frequent breaks and also be sure to set up your sawing station at a height that is comfortable for you. Everyone – yes EVERYONE – breaks blades, and you’ll notice yourself getting your face closer and closer to your project.

It is always a good idea to wear safety glasses while you are sawing. You will (er, I did) break lots of blades and have tons of problems if you try to hang your metal off the edge of a table rather than supporting it on both sides of that V. It does, however, take that V-cut bench pin. It doesn’t take much pressure to keep your metal in place. Hand cramps hurt, so take frequent breaks and be conscious of what you’re doing. One of the most difficult things at first is not pressing too hard with the hand that’s holding the metal down. Moving too quickly, especially when changing direction, is an easy way to break your blade. If the blade seems to be catching or it feels jerky, check your tension and/or apply a little lubricant to the blade. Blow away the shavings every so often so you can stay true to your pattern.

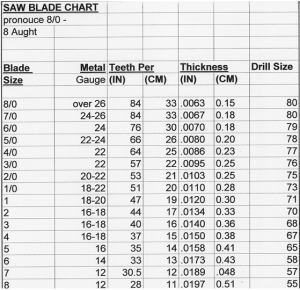

JEWELRY SAW BLADE SIZES HOW TO

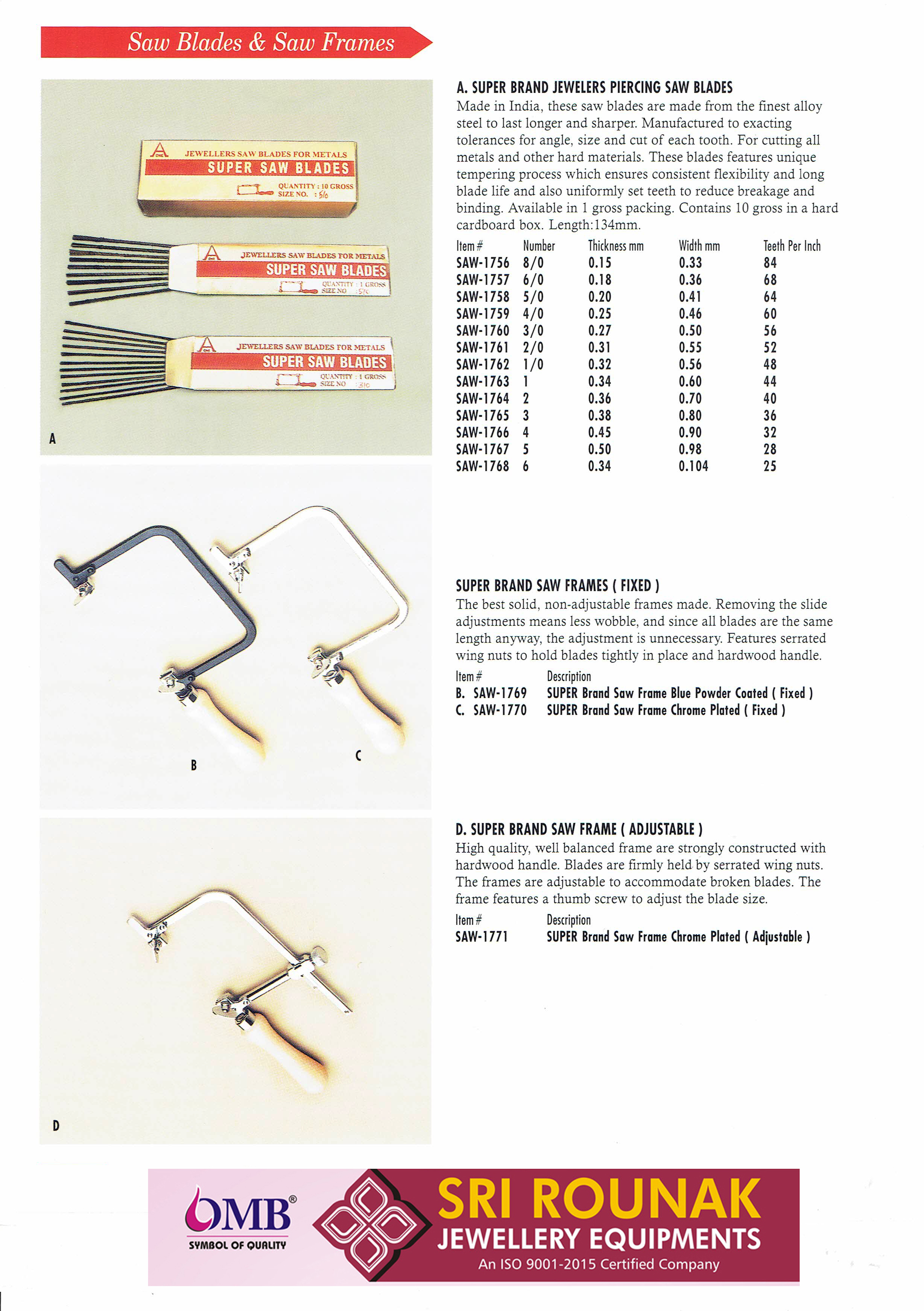

I try to keep the saw fairly stationary and rotate the metal to follow my pattern.įollow your design! It takes practice, but you’ll pretty quickly learn how to maneuver your metal and/or saw to follow curves. (If you haven’t used a jeweler’s saw before, see post about Knew Concepts frames and tensioning.) Make sure you have the blade in there good and tight – a loose blade very quickly becomes a broken blade! Tension is key. Insert saw blade into saw frame with the teeth pointing out (away from frame) and down (towards floor). The lubricant is meant to keep the blade moving easily across the metal, but sometimes it gunks up the shavings and clogs the blade, so use it sparingly at first.Īdhere your design to sheet metal with rubber cement and let dry.

Many people swear by it, but I typically prefer to saw without it.

I think the higher quality is worth the price for less breakage, but it is up to you.

0 kommentar(er)

0 kommentar(er)